In the process of glass combining, it is necessary to ensure that the indoor air is dry. Aiming at the characteristics of low humidity in laminated glass composite room, a low humidity air treatment program suitable for the requirements of low humidity environment is proposed. In the production process of the glass industry, humidity is very important to the production technology. The production efficiency and quality of glass are related to humidity, especially the combination room in the glass industry, which has extremely high technical requirements. In the process of gluing the glass-jacketed sheet, it is necessary to ensure that the indoor air is dry. When the air humidity in the synthesis room is too high, the fine water molecules in the air will adhere to the surface of the film or glass. After high temperature and high pressure treatment, the fine water molecules puff and form white mist or bubbles in the glass. In severe cases, the glass Degumming.

If the water content in the film storage room is large, the film will absorb water, age and become brittle, which will affect the adhesion and adhesion of the film, reduce the strength of the film glass, and lose the importance of the safety glass itself. Therefore, it is important to strictly control the temperature, humidity and cleanliness of the laminating room in the production of laminated glass. The general process requirements for the environment are temperature t=22-26℃, relative humidity RH=30-40%RH, This humidity requirement can be achieved by using industrial dehumidifiers. In particular, the process requirements in the imported glass combining chamber are: temperature t=20 -26℃, relative humidity φ≤30%. In this case, only a combined rotary dehumidifier can meet such process requirements.

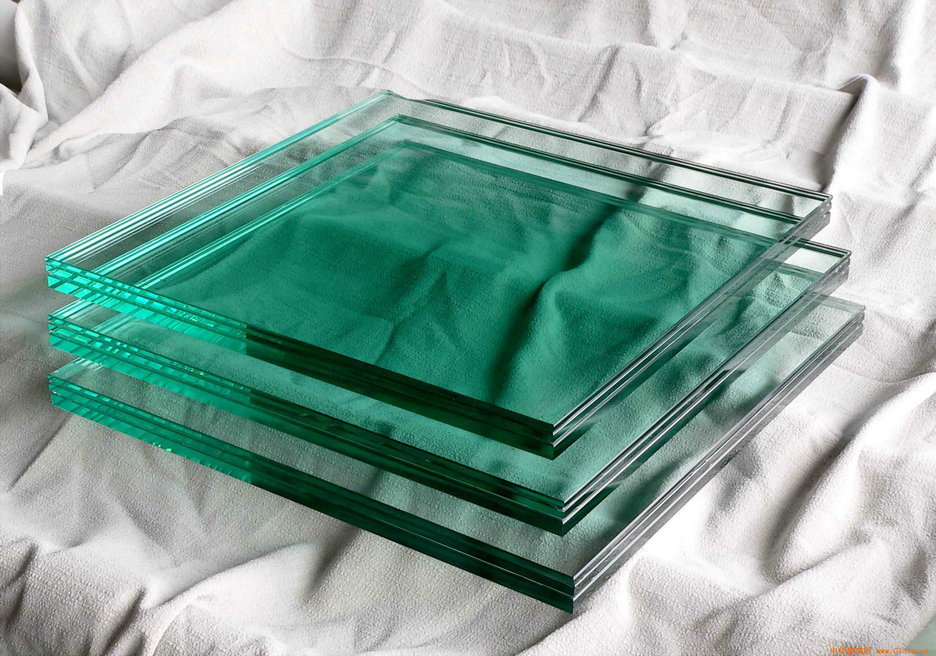

In the production process of glass laminated glass, it has to go through many processes. The more critical one is the laminated process. The quality of the laminated glass directly determines the quality of the laminated glass; this process must be at constant temperature, humidity, and cleanliness. It is carried out in a high-degree combining room; there are three major requirements for the quality of laminated glass combining (1) optics (2) mechanics (3) environment. Especially the mechanics, that is, the bonding strength, and the strength depends on the water content of the film. Generally speaking, the water content of PVB film in production, production, transportation, and storage is below 2%; An environment with constant temperature and humidity and cleanliness up to the standard will cause the film to absorb moisture and increase its water content, which will hinder the adhesion between the glass and PVB. During production and use, due to temperature changes, the water vapor expands , Shrinkage, will produce bubbles, degumming or misty water vapor, affect the optics, and make the product scrapped.

Combination should be carried out in a combination room that meets the technological requirements: 1. The cleanliness must be high, and the cleanliness should be purified to one hundred thousand level; 2. The staff should have clothing and tools suitable for the purification conditions; 3. The room temperature of the combination The relative humidity of 25 soil 2 ℃ is about 25%; 4. The upper and lower glass interlayers should be aligned, and the stack difference should not exceed about 1.5 mm; 5. The PVB film and the glass interlayer should be kept clean. After the glass is laid flat in the composite room that meets the process requirements, the PVB interlayer film is spread out on the glass, and another piece of glass is placed. Use a knife to trim and cut off the PVB interlayer. Do not pull the PVB interlayer forcibly during trimming to avoid deformation of the PVB interlayer, and ensure that the margin of the PVB interlayer outside the glass is in the range of 2-5MM. When trimming, the blade must not be in contact with the glass, so as to prevent the generated glass particles from causing bubbles after processing.

The brand NAISIDA of Guangdong Aoyu Electric Appliance Co., Ltd. mainly develops and sells "household dehumidifiers, commercial dehumidifiers, industrial dehumidifiers, fresh air purifying dehumidifiers, cooling dehumidifiers, temperature regulating dehumidifiers," with constant temperature and humidity series products. Constant temperature and humidity machine, rotary dehumidifier, ultrasonic humidifier, wet film humidifier and non-standard product development".