"Air humidity" refers to the amount of water vapor in the air. The higher the humidity, the more humid the air. Humidity in the air is as ubiquitous as temperature. Air humidity not only affects people's daily life, but also has a great impact on industrial production. Industrial products are damp, which affects product quality; production equipment is damp and malfunctions, which affects production efficiency. The humidity of the environment is controlled to meet the conditions of the processing technology, and at the same time, it can provide people with a comfortable production environment.

Industrial dehumidifiers are now running in many factories or enterprises to control the relative humidity of the environment and are used for moisture prevention and dehumidification in workshops, warehouses, and laboratories. Although the ultimate purpose of industrial dehumidifiers is the same, there are many types of industrial dehumidifiers, and the correct selection is also very important. If you choose a dehumidifier with too small dehumidification capacity, not only the dehumidification effect will not be achieved, but the dehumidifier will also be damaged due to long-term operation; if you choose a dehumidifier with too much dehumidification capacity, even if it can achieve the purpose of dehumidification, it will cause the dehumidifier Frequent opening and shutdown can damage the machine and consume power at the same time.

So, how can we correctly select the type of industrial dehumidifier?

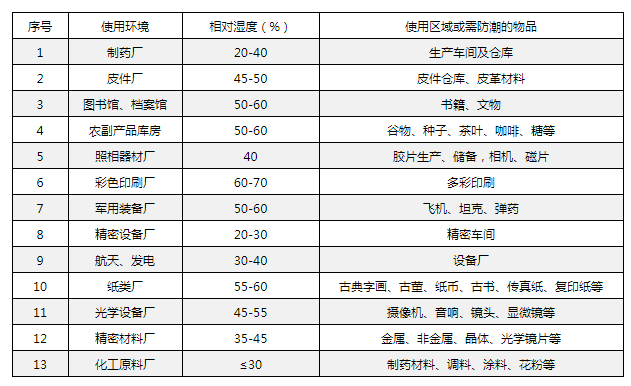

First of all, you need to be clear about your own needs and choices. The humidity of the environment in the production workshops of different industries is different. Some require a relatively dry environment, so the requirements for the specific humidity of the product are even lower. At the same time, according to different workshop environments, it is necessary to choose which product is suitable for ceiling-mounted or wall-mounted products to ensure that the product effect is maximized.

Humidity requirements of production workshops in different industries

The second is to understand the function of the product, and select the model based on the functional requirements. Because some industrial production requires functions such as sterilization and the release of negative ions; and starting from the operation, some production workshops require intelligence, which can control multiple industrial dehumidifiers through a computer system with one button.

To master the performance of industrial dehumidifiers, you can start with the following parameters, including dimensions (mm), fan power (KW), rated air volume (m3/h), cooling capacity under fresh air conditions (kW), and fresh air conditions Heating capacity (kW), noise db(A), weight (kg), rated water volume (m3/h), cooling capacity under mixed conditions (kW), heating capacity under mixed conditions (kW), outlet pressure (Pa ), rated voltage (V), margin (m3/h), which can better improve work efficiency and reduce losses.

Naisida industrial dehumidifier introduces international-level dehumidification technology, integrating intelligence, humanity, and energy saving, and comprehensively solves the impact of moisture in large-scale office spaces, material storage and industrial production environments, such as damp items, production impacts, and instruments We strive to create a production environment with high efficiency and energy saving, precise humidity control, and improved efficiency for you with problems such as short circuit, bacterial growth, and limited process.