1. The process of meat drying

1. Isokinetic drying stage

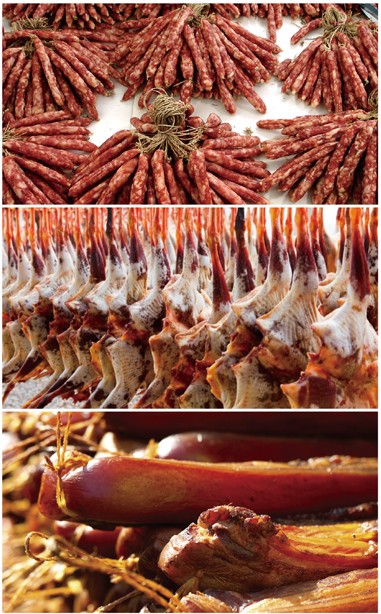

After 5-6 hours, the temperature of Naisida high-temperature dryer was increased to 60°C within two hours after it was installed in the barn. The purpose is to make the fresh sausages reach the same temperature inside and outside within 2 hours. The long temperature process is also a process of seasoning and meat fermentation, which can control the meat from changing color and taste. After the preheating time, adjust the temperature to 45-50°C and the humidity in the range of 50-55%. At this stage, the surface water has evaporated, and the color changes from the grayish white of the feed material to light red. This stage is the color-changing period, and then the sausage is taken out from the roasting room, and the head and tail of the sausage are hung upside down, and then sent to the roasting room and into the waxed sausage.

The second stage of drying process.

2. Reduced drying stage

It lasts for 15-18 hours, and it has two phases of color development and a contraction and setting phase. In the second stage of color development, the temperature is controlled at 52-54°C for 4-6 hours, and the humidity is controlled at 45%. The sausage gradually changes from light red to bright red, and the casing begins to shrink. In order to prevent the surface of the casing from forming a hard crust, after the color development period, it must be treated with ventilation and cooling. The drying and dehumidifier stop heating, open the moisture outlet to discharge the hot and humid air, and add cold air for cold air to dry and noisy, so that the sausage can be dried. The skin temperature drops rapidly, which is conducive to the migration of water from the water inside the anorectal to the surface. The contraction setting period and the contraction setting period lasts 11-12 hours. During this period, the water content in the sausage continues to decrease, the sausage shrinks significantly, and the appearance is uneven. The overall appearance has been determined. In the middle of the shrinkage setting, Start shrinking and setting for 5 to 6 hours, using half an hour of cold air cooling to alleviate the contradiction between surface moisture evaporation and internal moisture migration, until the end of shrinking and setting.

3. Rapid drying stage

The decisive factor restricting the drying speed in this stage is temperature. In order to strengthen the drying speed, the temperature is increased to 55-60℃, the drying time is controlled at 22-24 hours, and the relative humidity is controlled at about 35%. The sausage is finally dried. The humidity is controlled below 17%.

Second, the advantages of the Nystar drying and dehumidifier drying solution

(1) The fully automatic control system can select the best drying temperature and humidity according to the process requirements of different products, which completely solves the problems of long drying time, high temperature, and high energy consumption in other drying methods. It is unparalleled Table more features.

(2) The use of high-efficiency centrifugal fans has the characteristics of strong wind, uniform air flow, low noise, etc., and the materials are dried evenly and quickly.

(3) During the drying process, the material will not be deformed, cracked, discolored, degraded, not oxidized, thoroughly dried, rehydrated well after drying, less nutrient loss, long storage period, and more effectively protect the color and fragrance of the dried material , Flavor, shape and active ingredients.

(4) The integrated design of the unit can be used when the pipeline and power supply are connected on site; the operation is convenient. After setting the parameters, the automatic control can be realized with high reliability.

(5) Low investment and quick results. Old kilns, garages, etc. can be used for transformation, and it can be moved and save floor space. It is simple and convenient.

The brand NAISIDA of Guangdong Aoyu Electrical Appliance Co., Ltd. mainly develops and sells "household dehumidifiers, commercial dehumidifiers, industrial dehumidifiers, fresh air purifying dehumidifiers, cooling dehumidifiers, temperature regulating dehumidifiers," with constant temperature and humidity products. Constant temperature and humidity machine, rotary dehumidifier, ultrasonic humidifier, wet film humidifier and non-standard product development".

Previous : Edible fungus drying solution

Next : Wood drying solution

Mobile phone:13929191085 13422006435

E-mail:835727061@qq.com QQ:835727061

Address Factory:No. 28, Beihu 1st Road, Luocun, Shishan Town, Nanhai District, Foshan City