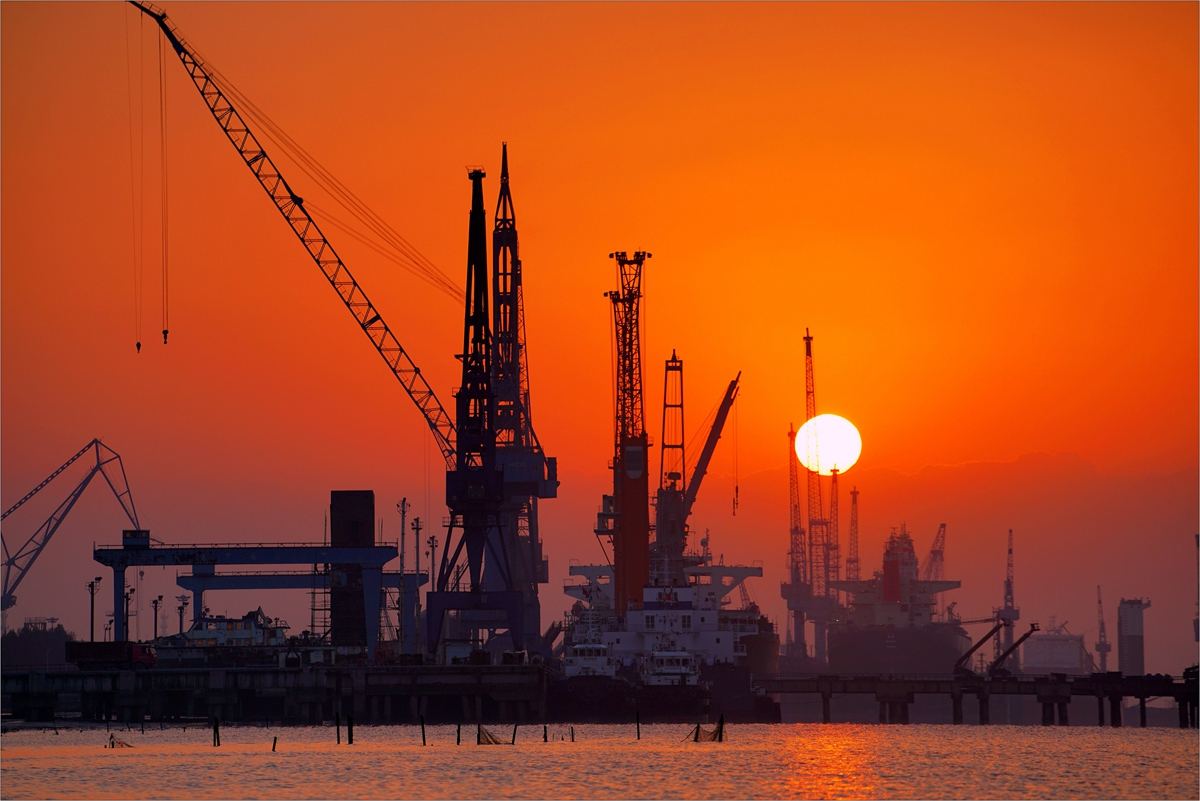

In the coating operation of the shipyard, the quality of the work depends to a large extent on the air humidity during the construction period. Because during the painting operation, the relative humidity is too high will often cause condensation on the painted surface, and painting on the surface with dew will cause the material to rust and reduce the effect of the coating. Therefore, in the coating process, shipyards often use rotary dehumidifiers for drying.

Using a dehumidifier for drying treatment can improve the overall coating process effect. In order to meet the requirements of dehumidifying the air throughout the year, the most commonly used dehumidifier uses a rotary dehumidifier to cooperate with general refrigerated dehumidification equipment. The dehumidification rotor requires high-temperature hot air for desorption and regeneration. The current conventional dehumidifier uses electric heating For regeneration, the heating energy consumption of regeneration is the main energy-consuming component of the dehumidifier, which usually accounts for more than 40% of the energy consumption of the system. Consuming a large amount of high-quality electric energy to generate heat causes the disadvantages of energy waste and high operating costs.

Therefore, in the entire coating process of the shipyard, the best thing to do is to use a rotary dehumidifier for continuous dehumidification to achieve the maximum coating process quality and increase the bonding force of the coating.

The brand NAISIDA of Guangdong Aoyu Electric Appliance Co., Ltd. mainly develops and sells "household dehumidifiers, commercial dehumidifiers, industrial dehumidifiers, fresh air purifying dehumidifiers, cooling dehumidifiers, temperature regulating dehumidifiers," with constant temperature and humidity series products. Constant temperature and humidity machine, rotary dehumidifier, ultrasonic humidifier, wet film humidifier and non-standard product development".

上一条:没有了!